Title

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Accordion content

Accordion content

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nullam nec tellus sed nisl tempor lacinia a et turpis. Fusce sit amet nisi tortor. Vestibulum vel odio nulla. Curabitur congue suscipit ante ut suscipit. Maecenas massa neque, iaculis et lobortis eu, ultricies quis leo. Sed sed dapibus neque. Mauris semper efficitur mi at suscipit.

In congue sit amet est quis faucibus. Aliquam tempus dolor non massa tempus vulputate. Aenean accumsan arcu quis orci scelerisque, vitae gravida enim maximus. Donec euismod lorem quis nisl varius, id interdum erat gravida. Sed non pretium enim. In hac habitasse platea dictumst. Praesent ornare posuere nisi. Phasellus sed lobortis orci, quis fringilla dolor. Integer non ligula enim. Donec eget suscipit ex.

Donec viverra lacus vel eros sollicitudin porttitor. Morbi molestie volutpat neque, eget blandit quam accumsan maximus. Praesent sem erat, vulputate ut tortor iaculis, pellentesque consequat nunc. Praesent feugiat nisl sed mollis auctor. Nullam ex ex, interdum quis scelerisque a, auctor at lorem. Donec et pretium justo. Nullam vulputate hendrerit enim a rhoncus. Integer auctor gravida risus, non blandit leo vestibulum vel. Quisque ut leo ac purus tempus mattis pretium ut est.

Donec viverra lacus vel eros sollicitudin porttitor. Morbi molestie volutpat neque, eget blandit quam accumsan maximus. Praesent sem erat, vulputate ut tortor iaculis, pellentesque consequat nunc. Praesent feugiat nisl sed mollis auctor. Nullam ex ex, interdum quis scelerisque a, auctor at lorem. Donec et pretium justo. Nullam vulputate hendrerit enim a rhoncus. Integer auctor gravida risus, non blandit leo vestibulum vel. Quisque ut leo ac purus tempus mattis pretium ut est.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

|

|

|

| Belt width | 1200mm or 1600mm |

|

|

|

| Capacity round | |

| Sandwich | 125* rows/min |

| Capacity round | |

| Base cake | 250* rows/min |

| Sandwich | 125* rows/min |

| Capacity rectangular | |

| Base cake | 160* rows/min |

| Sandwich | 80* rows/min |

|

|

|

| Product shapes | round, square, rectangular, others |

|

|

|

| Round | 25-100mm |

| Square | 25-100mm |

| Rectangular | 30-130mm, ratio min. 1,25 |

| Height | minimum thin products > 2,5mm |

|

|

|

| *rates depend on product shape, size and nature | |

|

|

|

| Belt width | 1600mm or 1800mm |

|

|

|

| Capacity round | |

| Sandwich | 180* rows/min |

| Capacity round | |

| Base cake | 360* rows/min |

| Sandwich | 180* rows/min |

| Capacity rectangular | |

| Base cake | 260* rows/min |

| Sandwich | 130* rows/min |

|

|

|

| Product shapes | round, square, rectangular, others |

|

|

|

| Round | 25-100mm |

| Square | 25-100mm |

| Rectangular | 30-130mm, ratio min. 1,25 |

| Height | minimum thin products > 2,5mm |

|

|

|

| *rates depend on product shape, size and nature | |

|

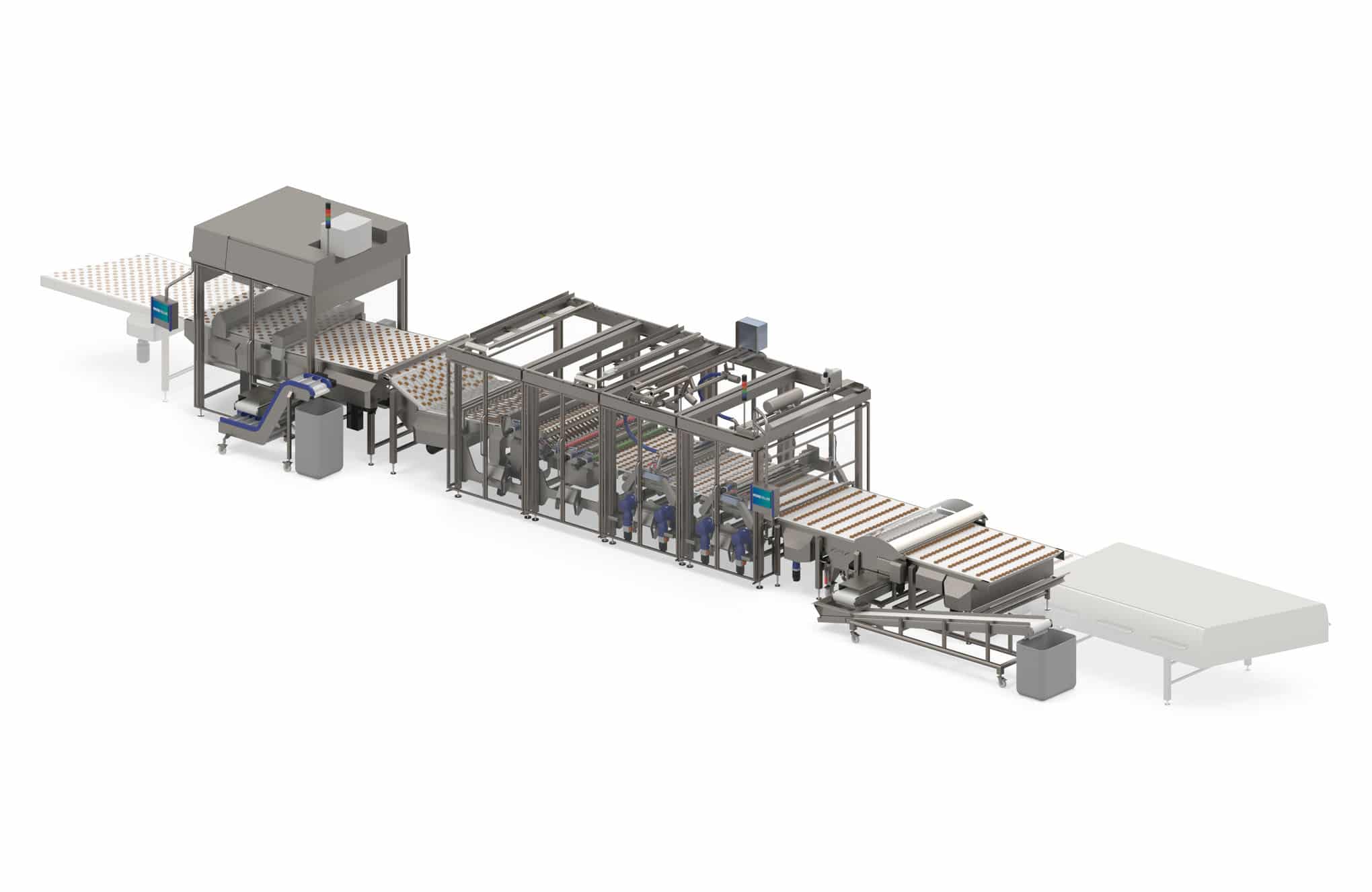

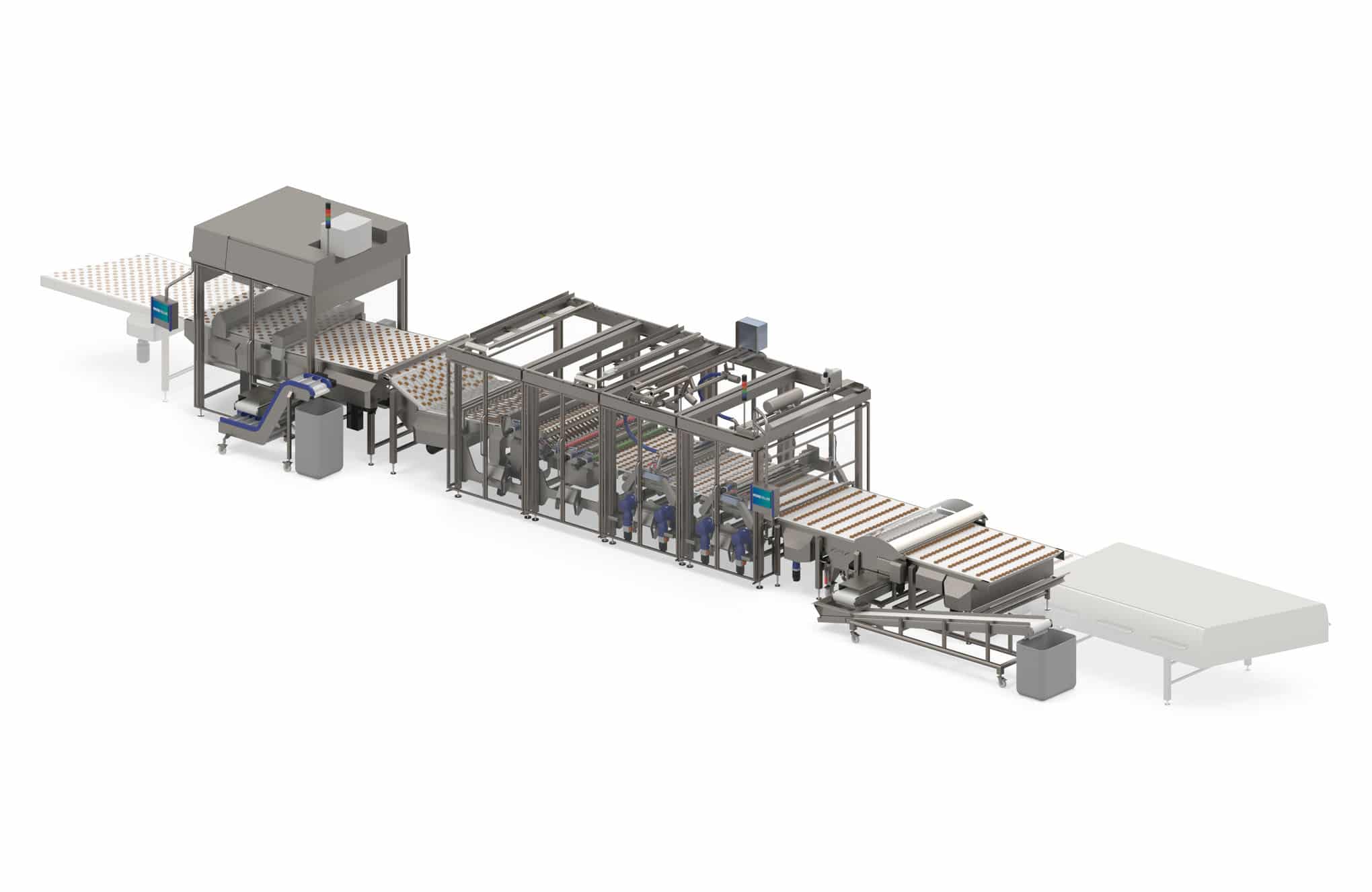

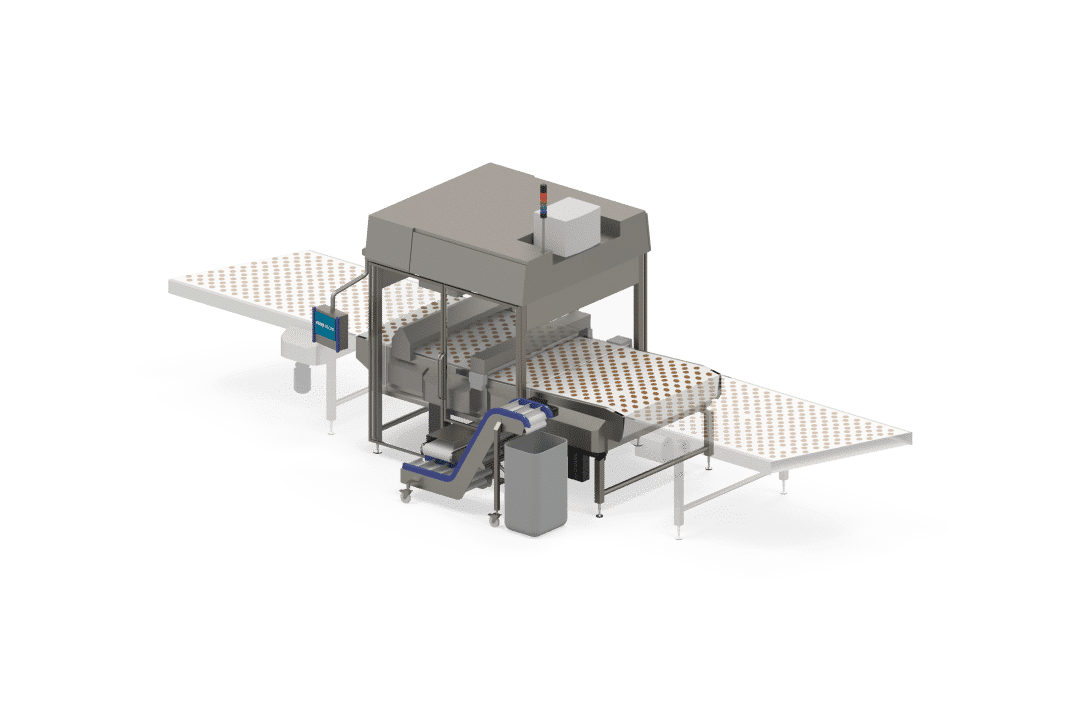

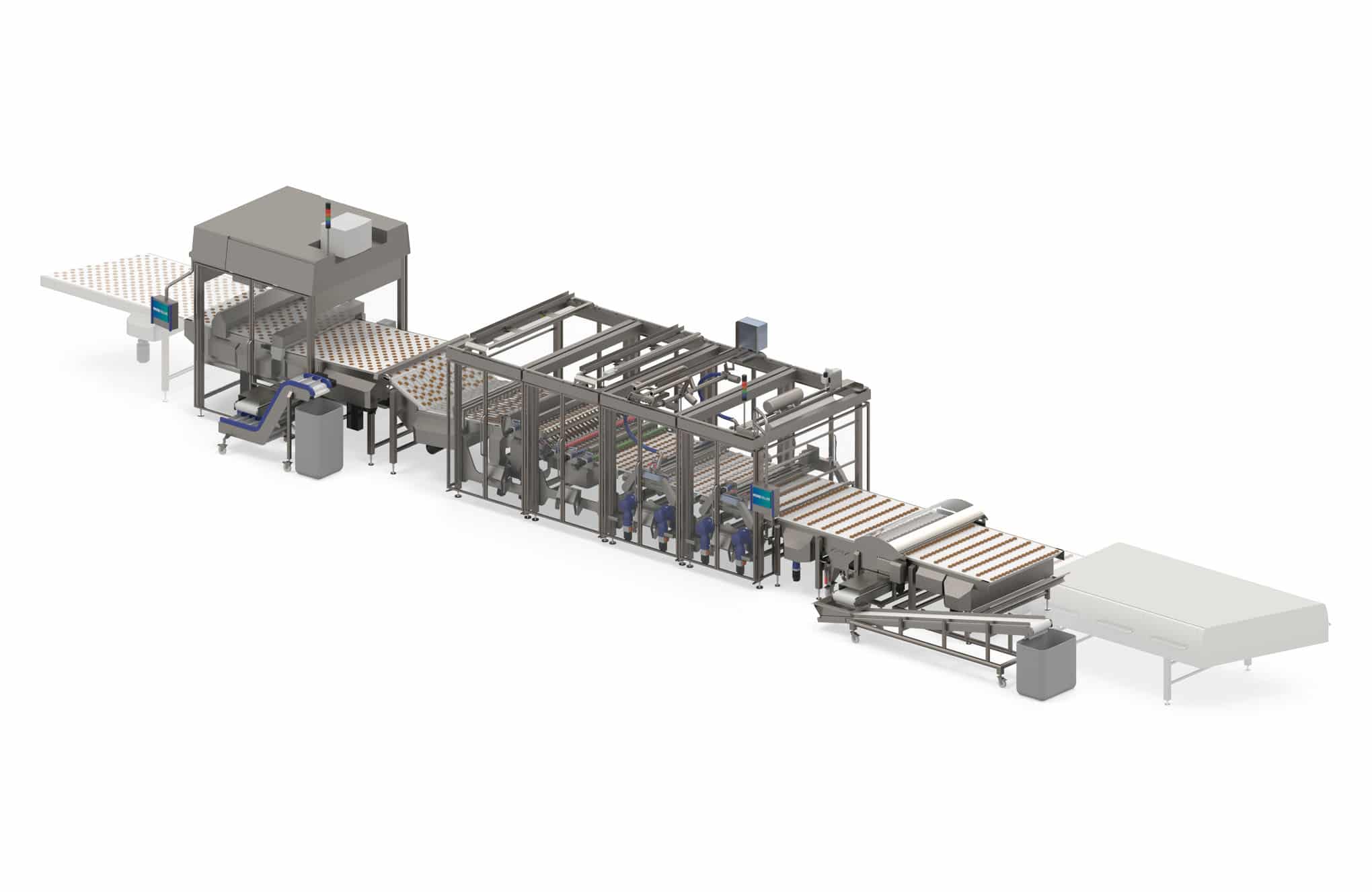

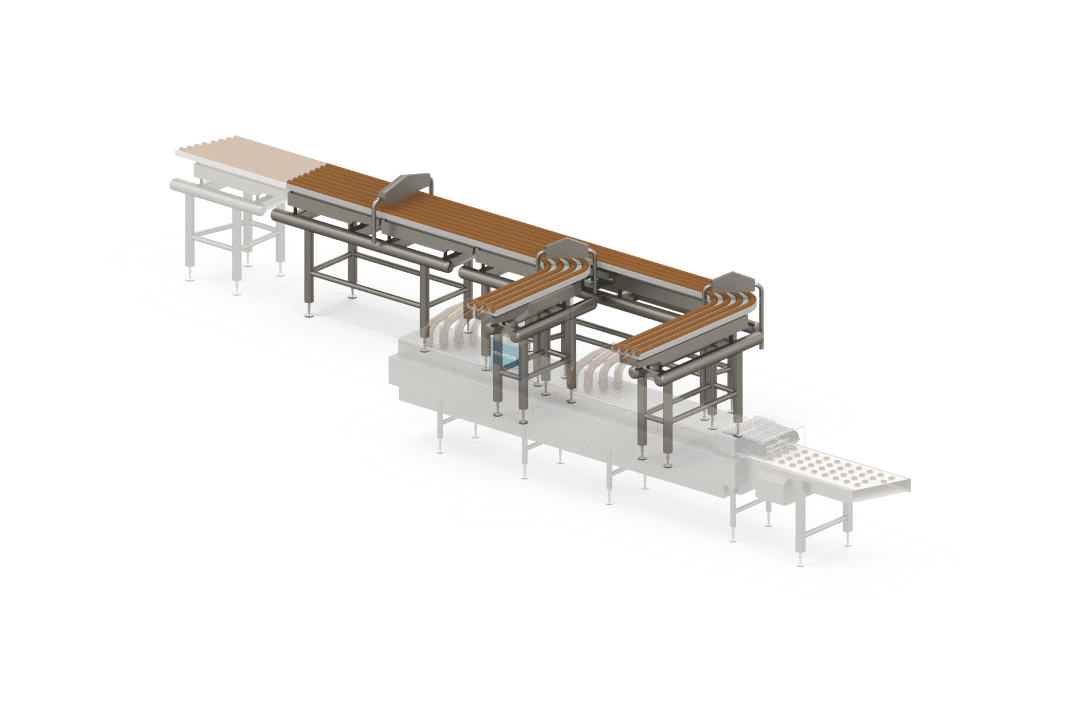

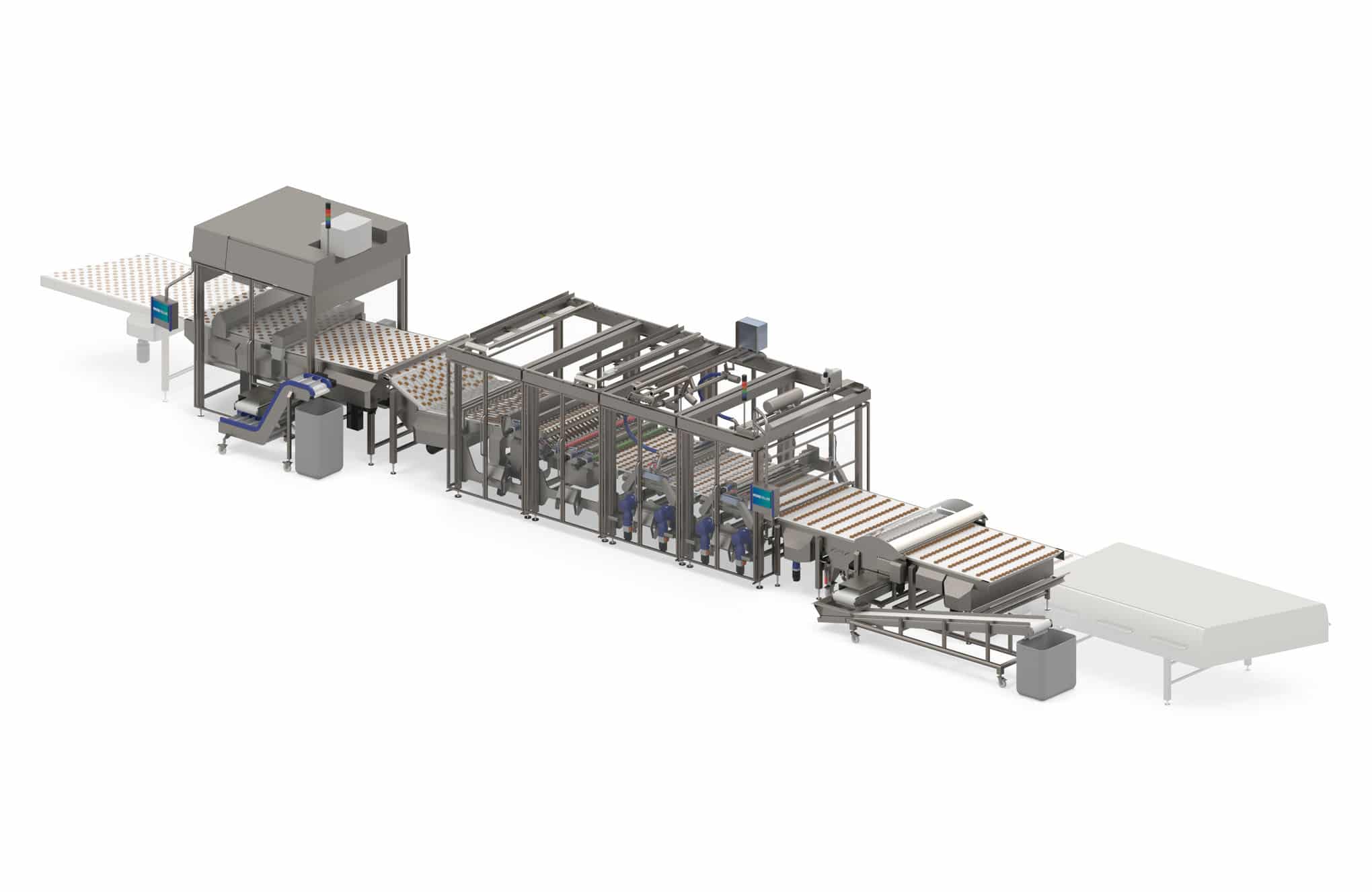

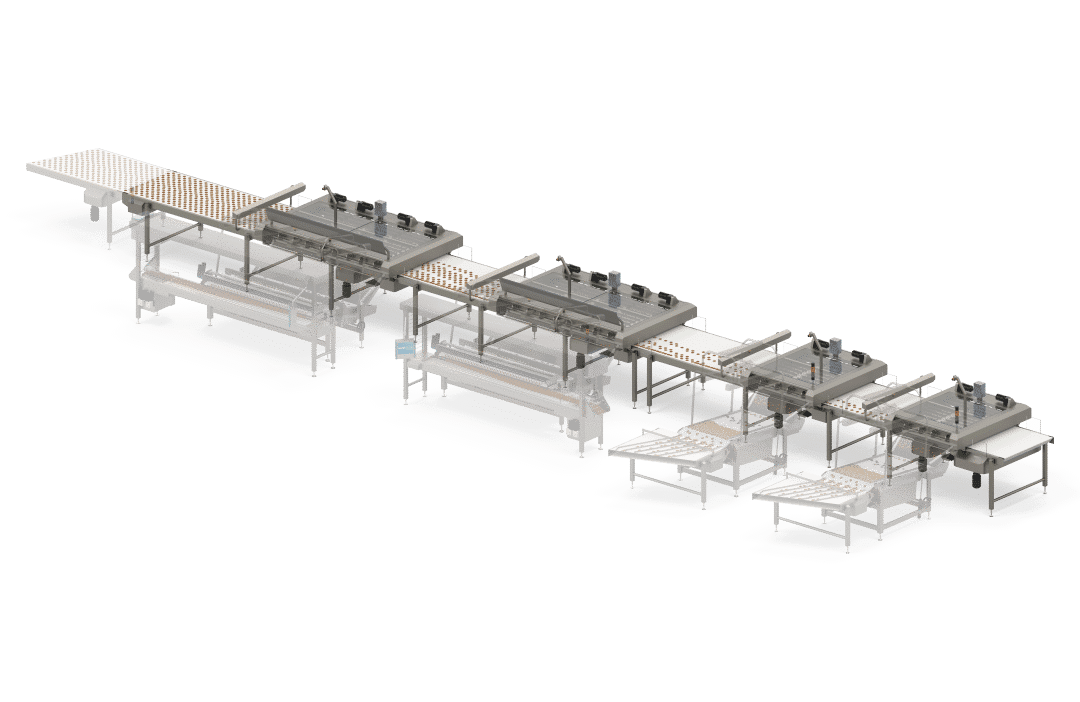

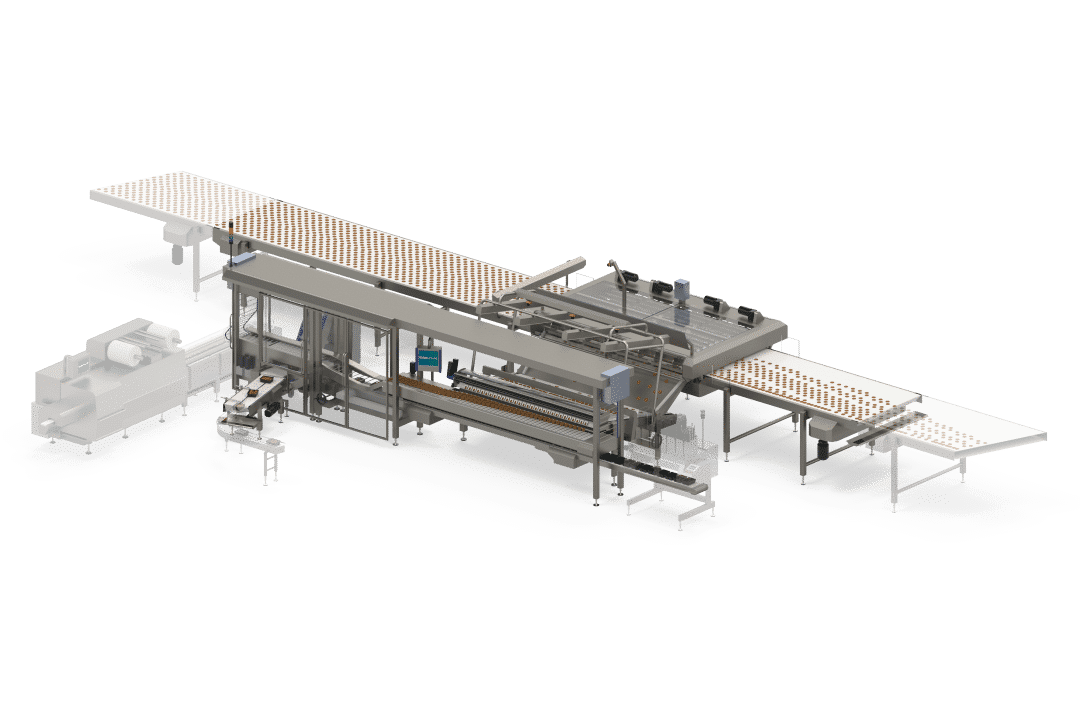

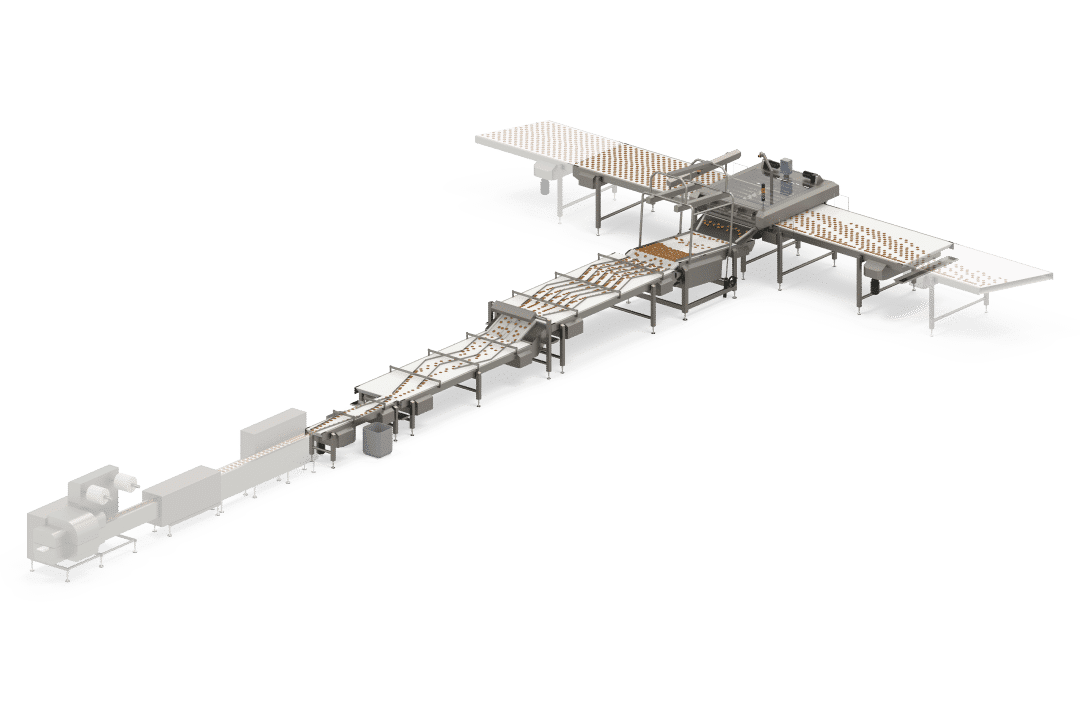

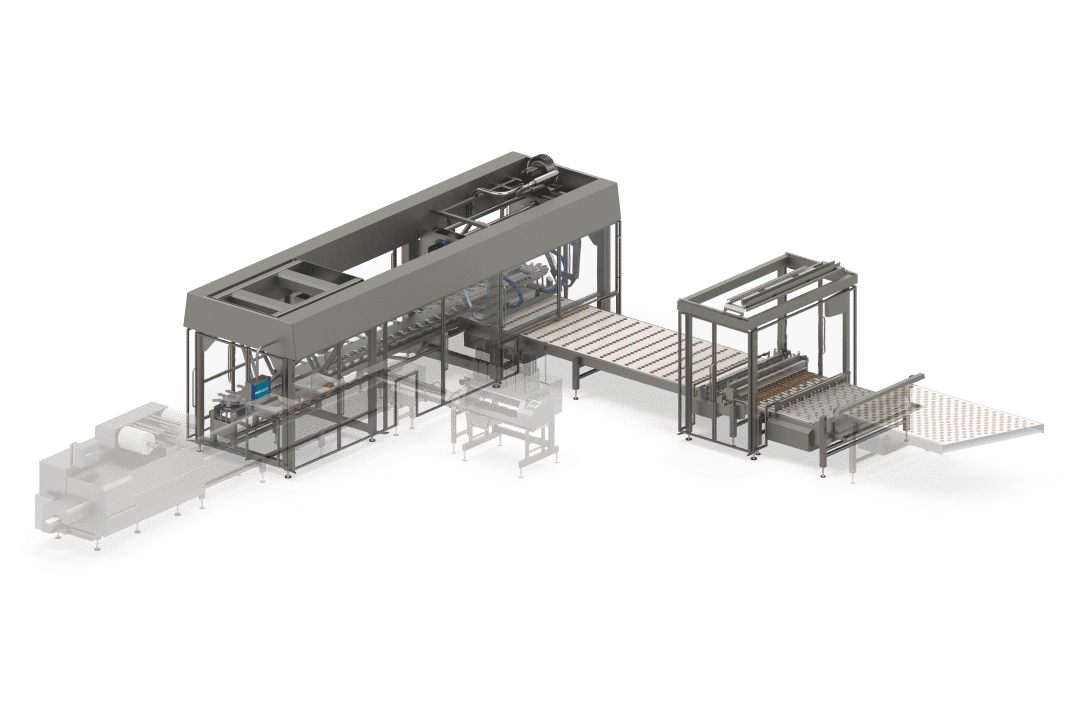

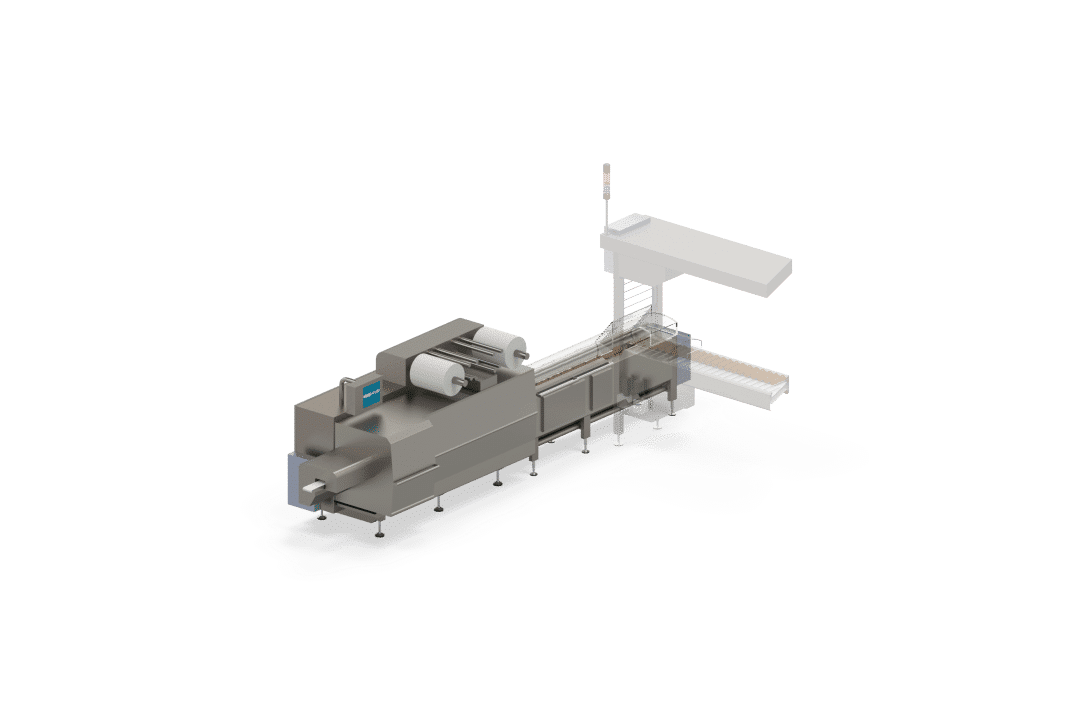

HOUDIJK CAPPER Mark II

The Houdijk Capper Mark II is a full option executed system.

|

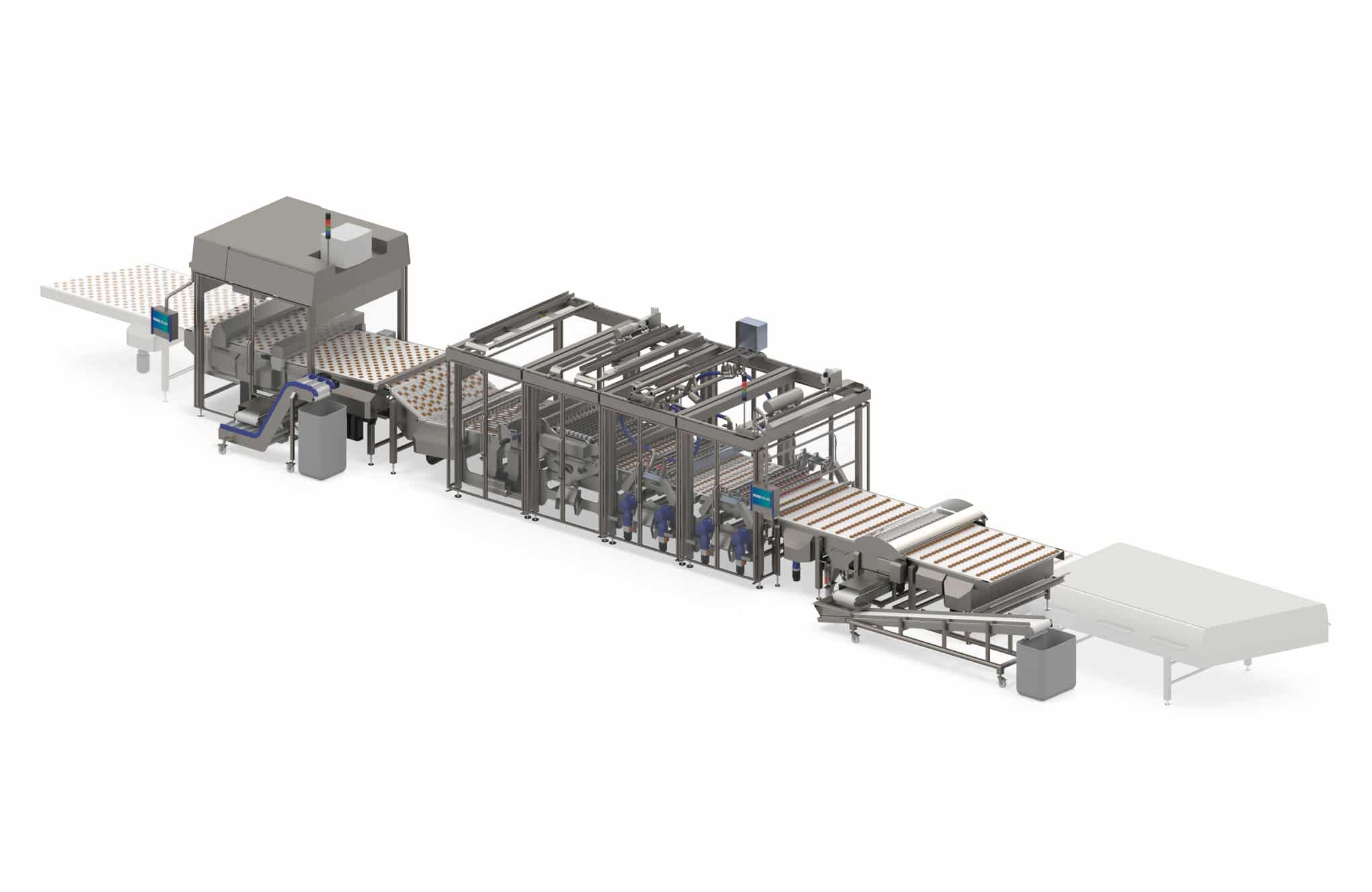

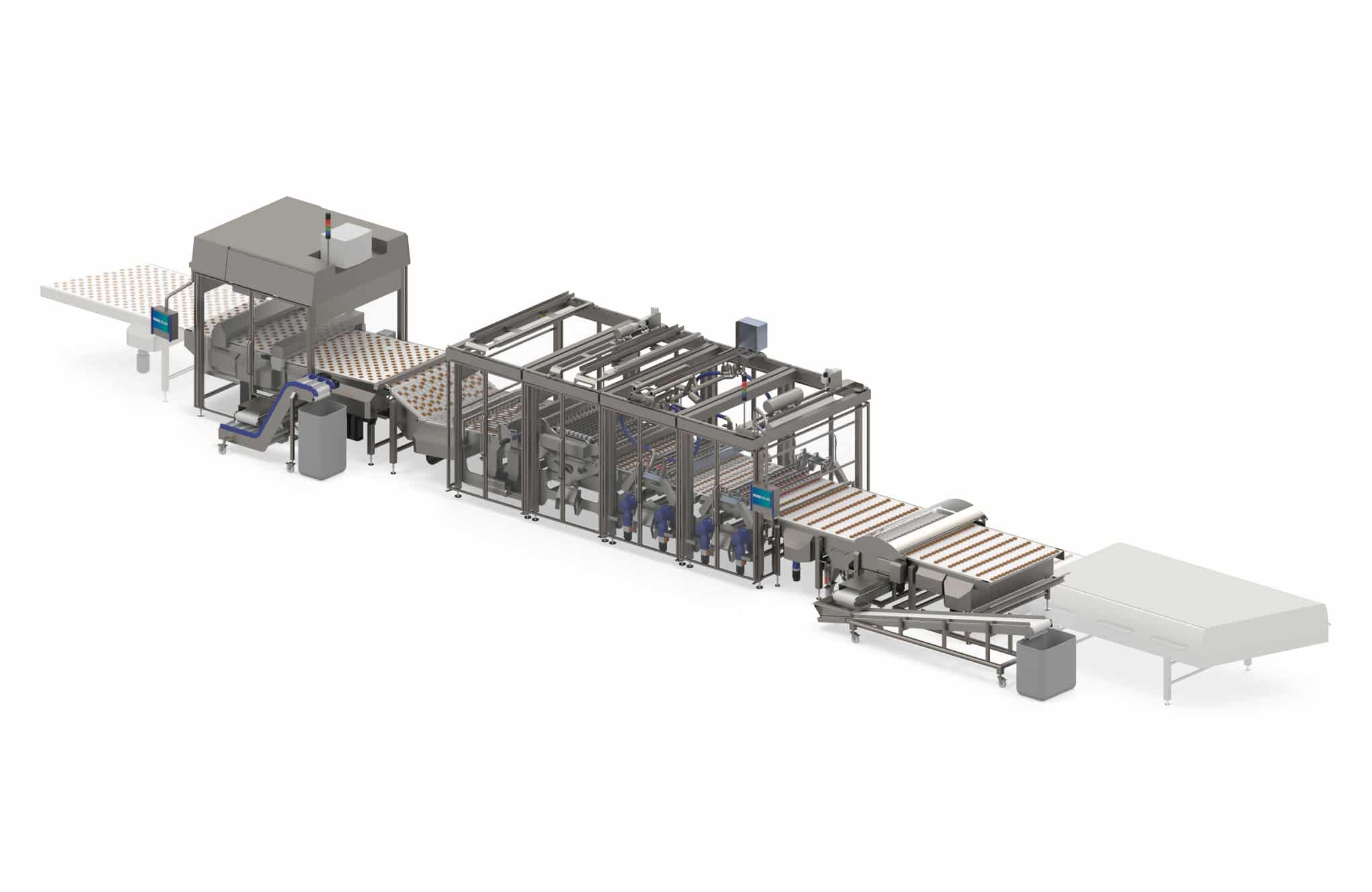

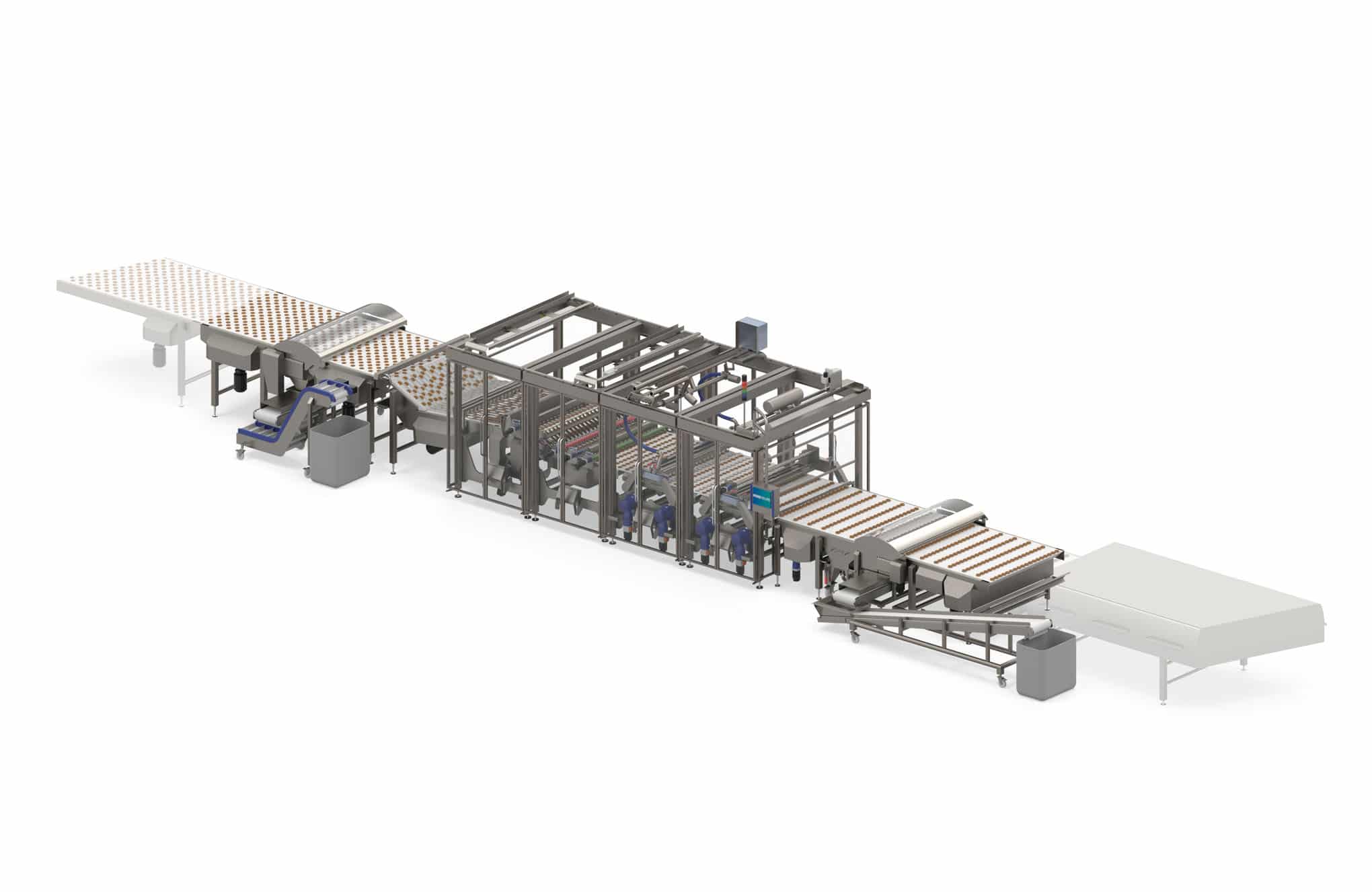

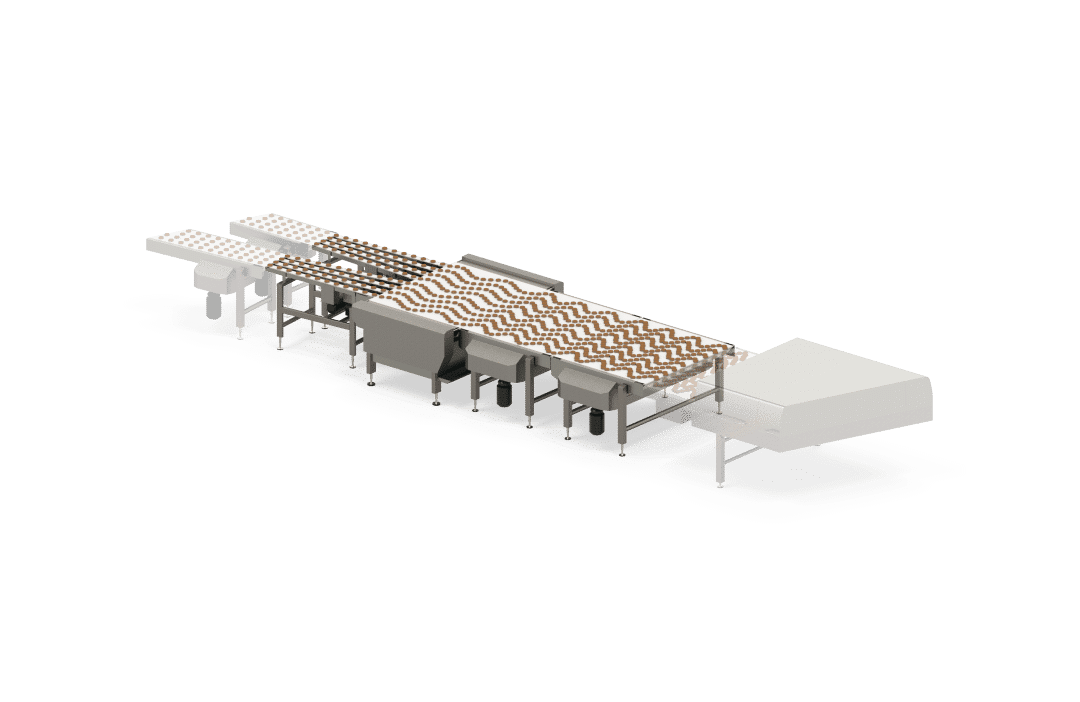

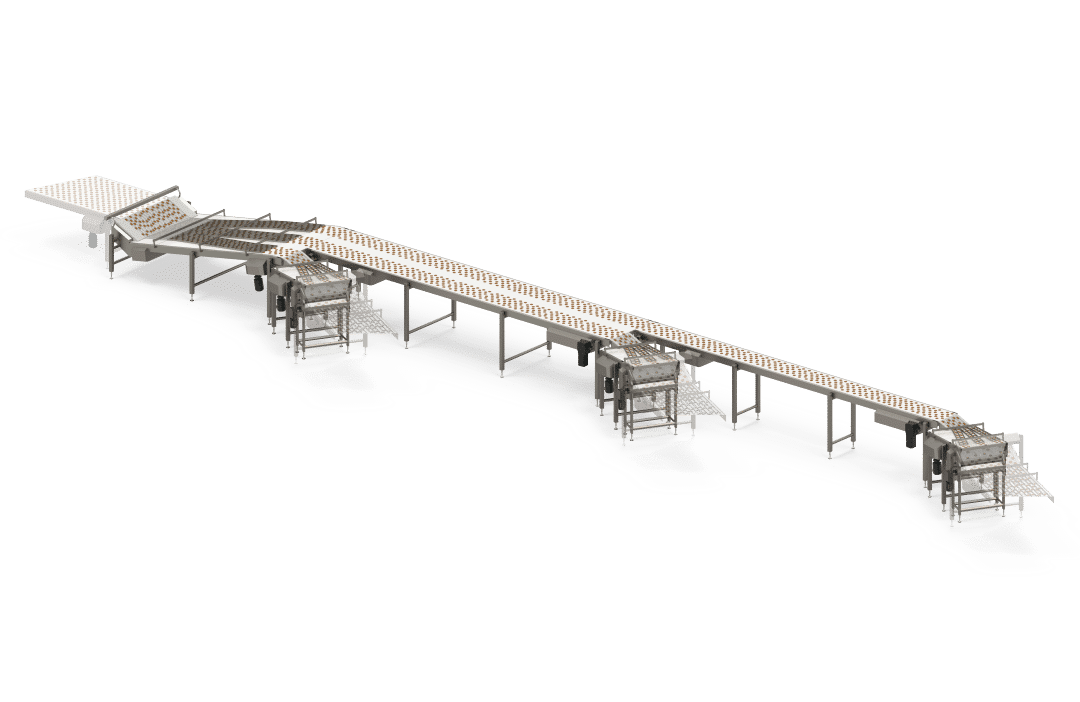

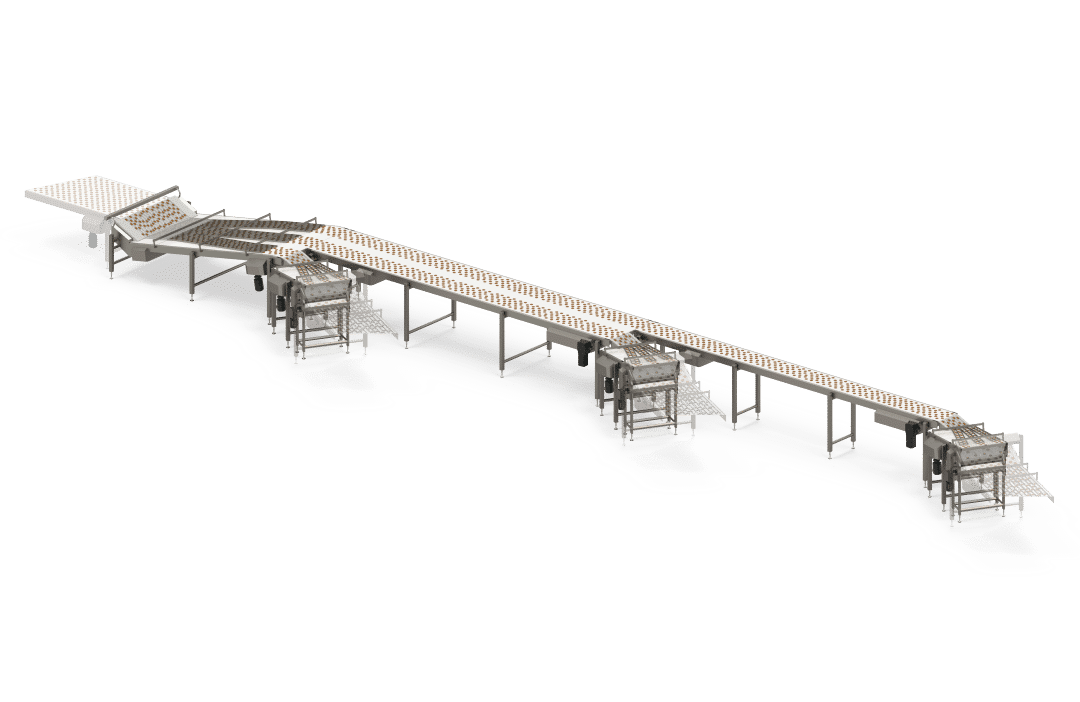

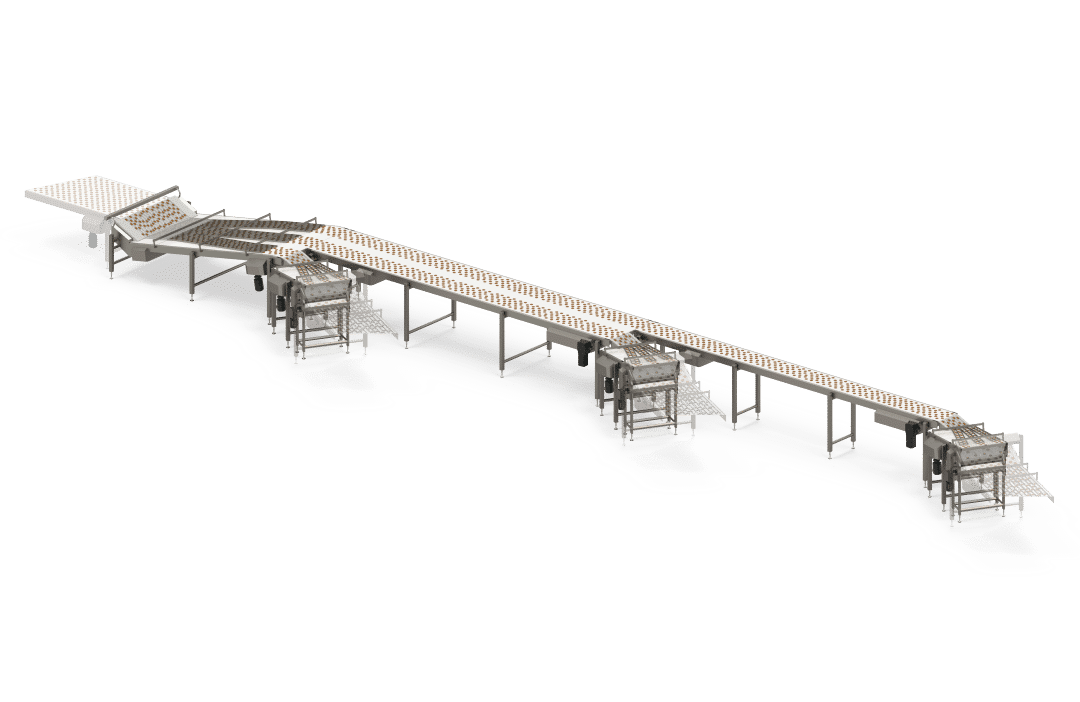

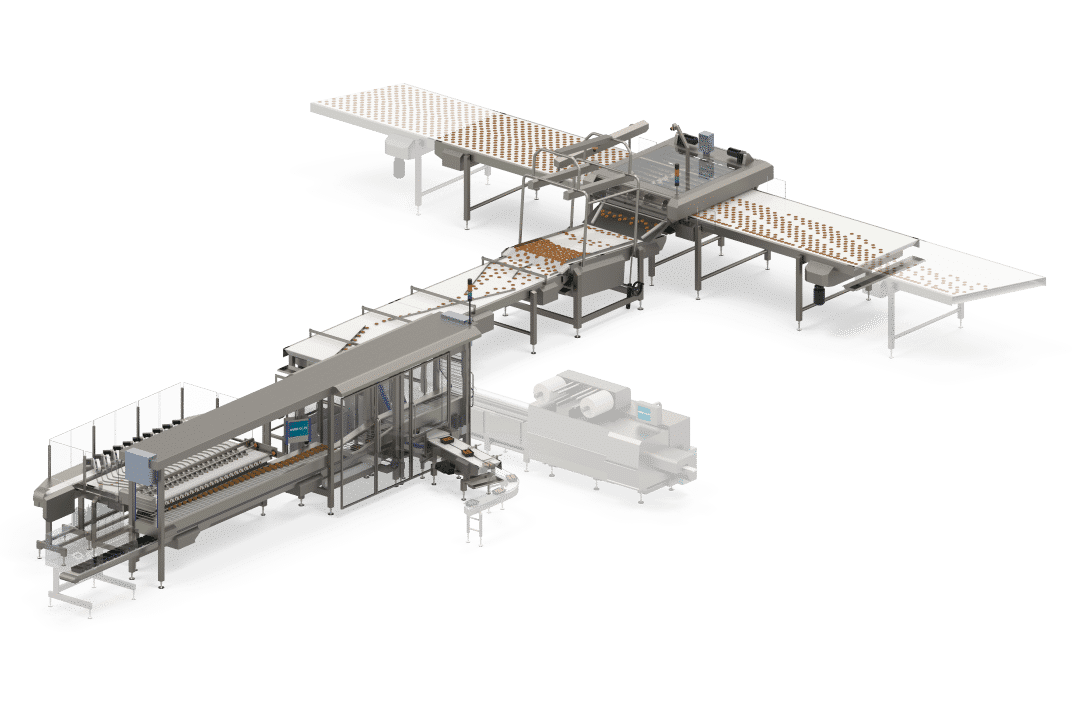

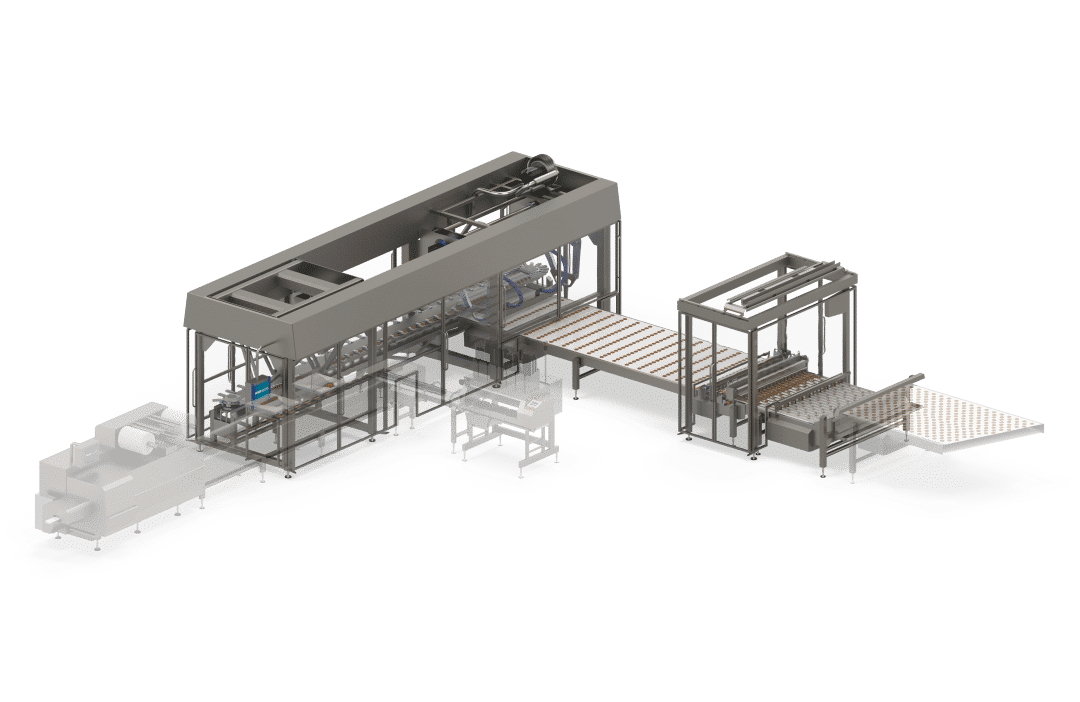

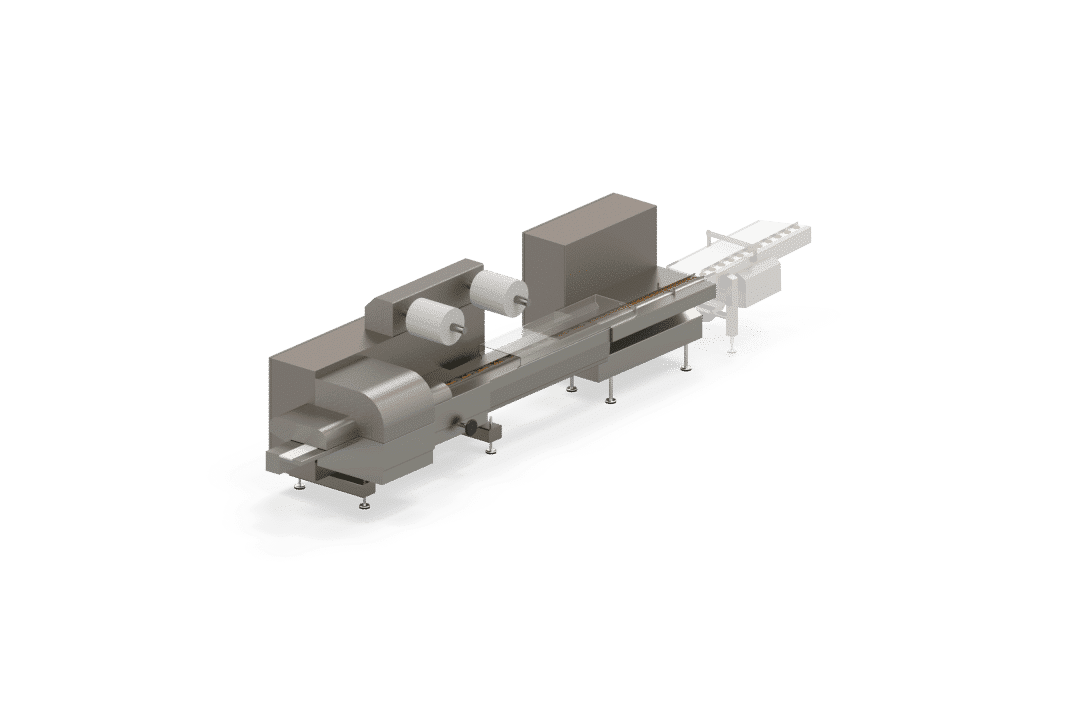

HOUDIJK CAPPER Mark III

The Houdijk Capper Mark III is a full option executed system.

|

|

|---|---|---|

|

|

|

|

| Belt width | 1200mm or 1600mm | 1600mm or 1800mm |

|

|

|

|

| Capacity round | ||

| Base cake | 250* rows/min | 360* rows/min |

| Sandwich | 125* rows/min | 180* rows/min |

| Capacity rectangular | ||

| Base cake | 160* rows/min | 260* rows/min |

| Sandwich | 80* rows/min | 130* rows/min |

|

|

|

|

| Product shapes | round, square, rectangular, others | round, square, rectangular, others |

| Round | 25-100mm | 25-100mm |

| Square | 25-100mm | 25-100mm |

| Rectangular | 30-130mm, ratio min. 1,25 | 30-130mm, ratio min. 1,25 |

| Height | minimum thin products > 2,5mm | minimum thin products > 2,5mm |

|

|

|

|

| *rates depend on product shape, size and nature | *rates depend on product shape, size and nature |

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Optional introduction: Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.

Maecenas hendrerit placerat tellus ac consequat. Quisque fermentum libero felis, et condimentum felis pretium efficitur. In rutrum egestas tincidunt.