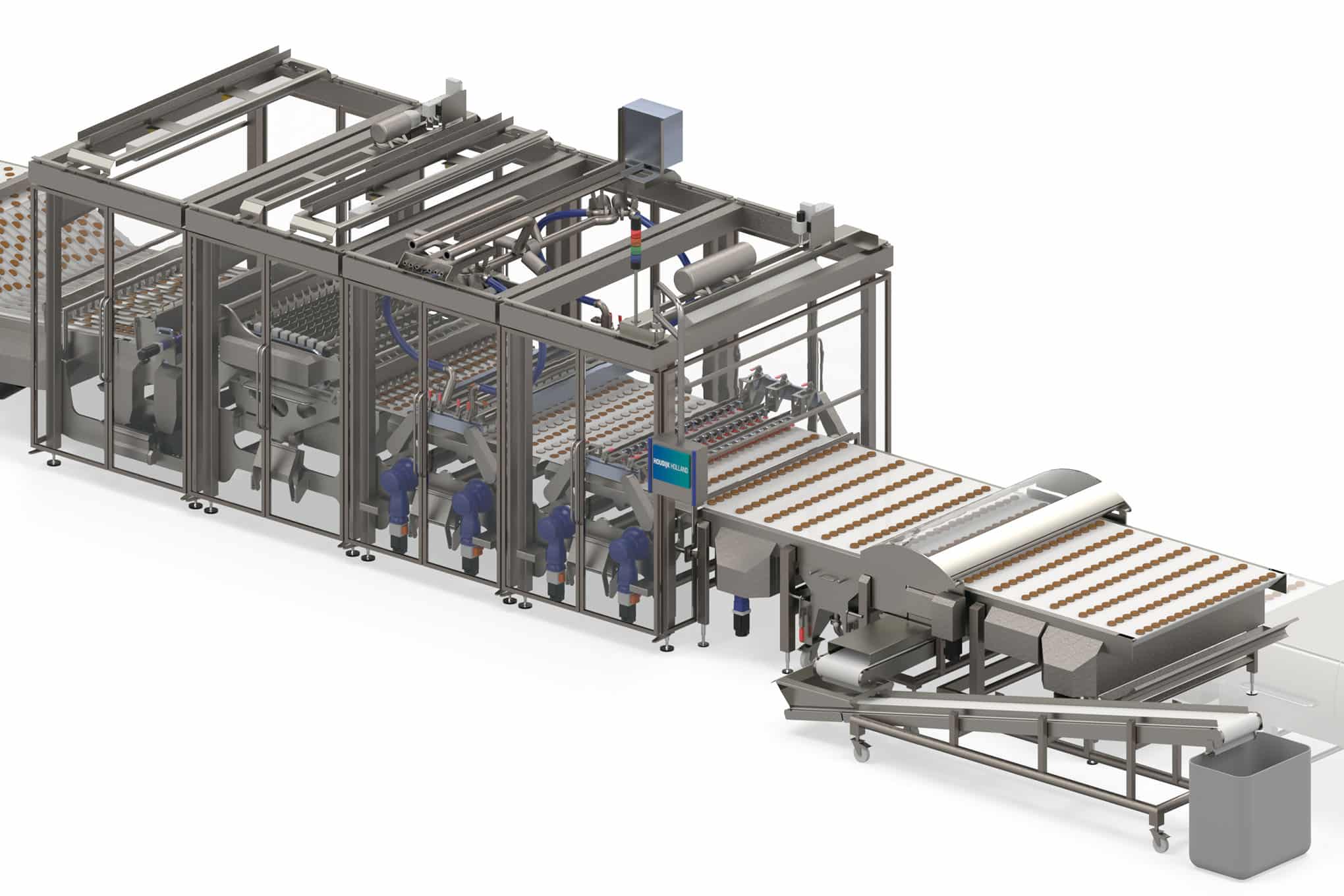

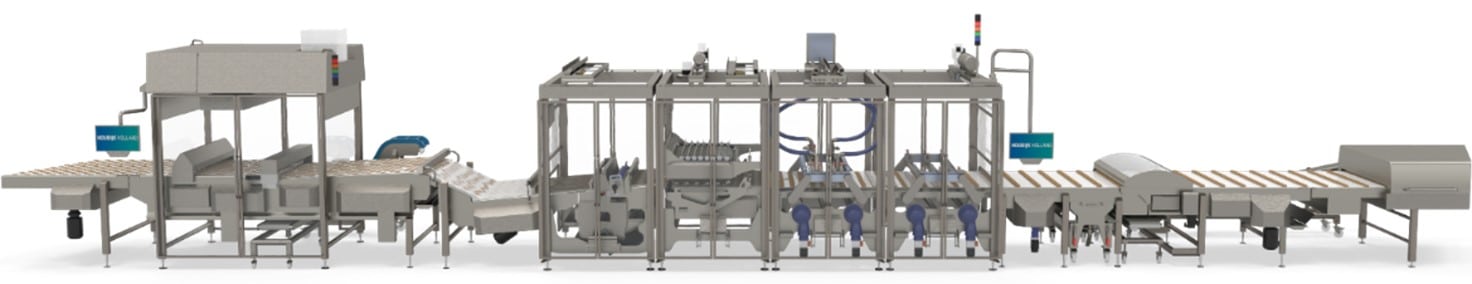

At the Interpack show Houdijk will introduce the COOKIEBOT XP which – Houdijk feels very confident – is an innovation that will change the biscuit industry. The vision guided robotic pick & place solution is able to manage a random product supply and offers the ultimate flexibility regarding different product types, sizes and shapes.

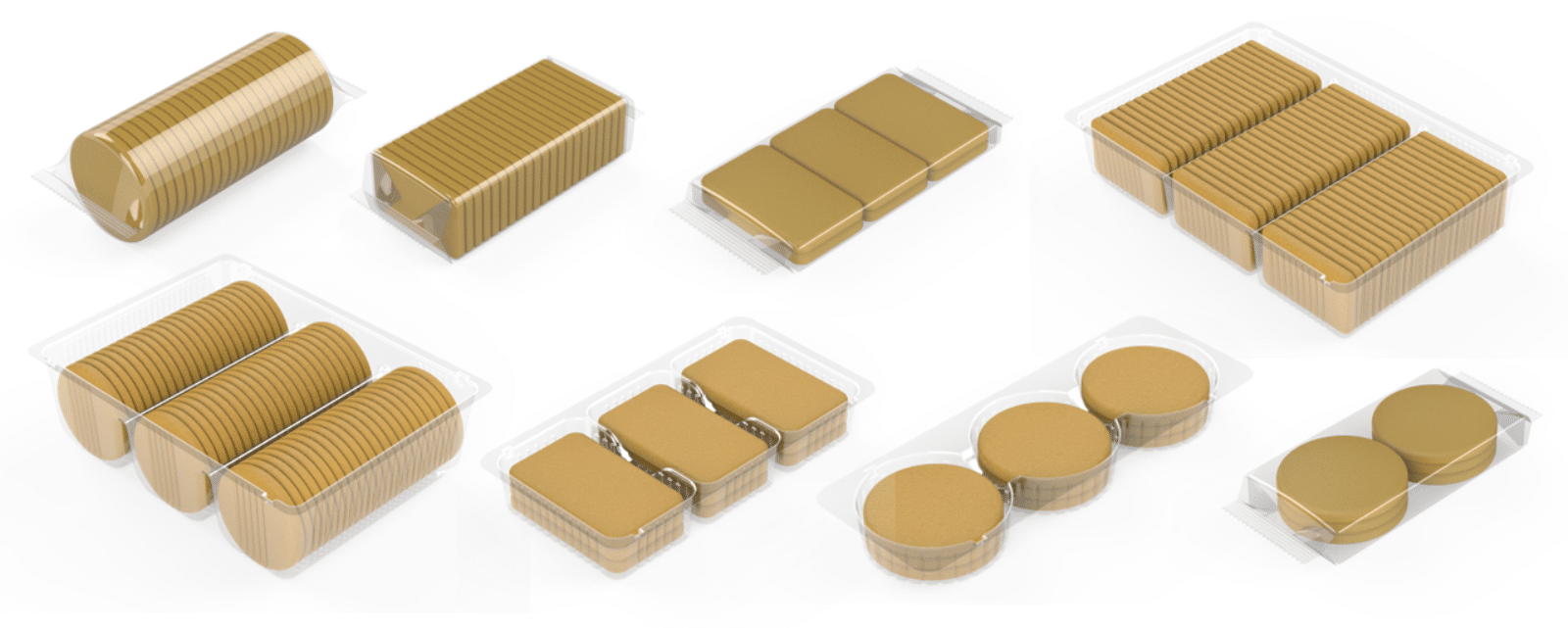

The vision guided robotic pick & place solution is able to manage a random product supply and offers the ultimate flexibility regarding different product types, sizes and shapes. Next to the conventional vacuum style product pickers, the COOKIEBOT XP can be executed with the patented SLUG GRIPPER to create a variety of different packaging configurations such as

Next to the conventional vacuum style product pickers, the COOKIEBOT XP can be executed with the patented SLUG GRIPPER to create a variety of different packaging configurations such as

- slugs with or without trays

- piles with or without trays

- individual products

The toolless exchangeable size parts are designed according POKA YOKE philosophy which secures simple and fast change overs and digital production startups.

The toolless exchangeable size parts are designed according POKA YOKE philosophy which secures simple and fast change overs and digital production startups.

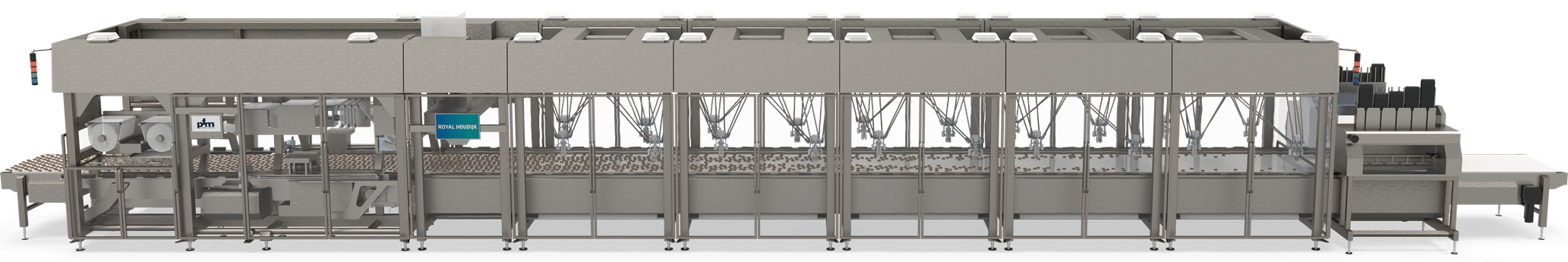

Via a magnetic driven lug chain, slugs, piles or trays are fed to and into the integrated PFM flow-wrapper featuring a patented box motion cross seal unit. PFM – a renowned family owned Italian packaging machine manufacturer – constantly works towards helping its customers to achieve success. The strength of the PFM Group lies in its original technological ideas, in its perseverance to create new ones and its absolute determination to be always one step ahead.

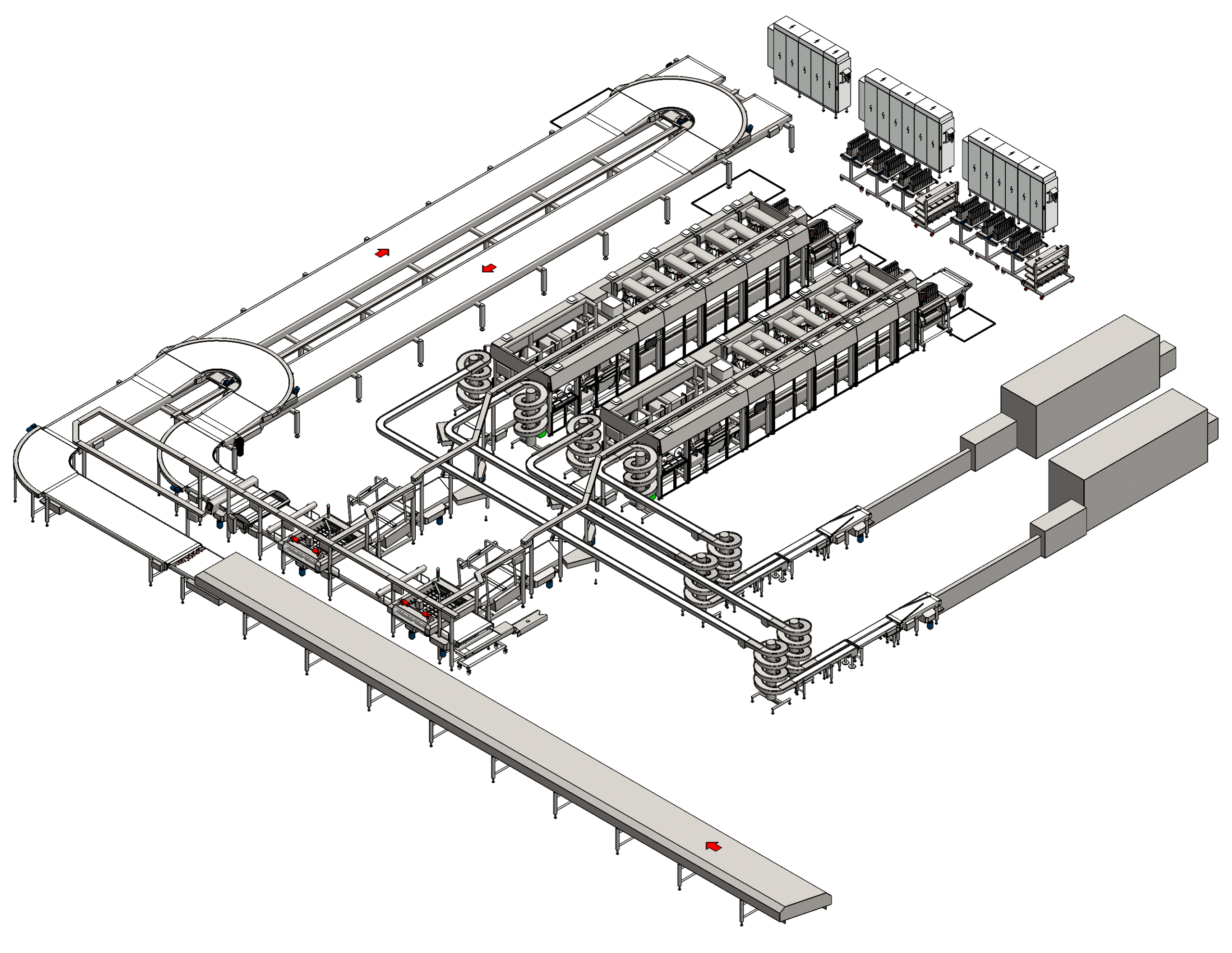

The COOKIEBOT XP in combination with the INFLOW BUFFER and product distribution allow – highly efficiently – to integrate several COOKIEBOT legs in one solution to meet the desired capacity. The flexibility and high capacity are supported by several additional standard features securing a guaranteed overall efficiency of 99+% with one supervisor only concluding in the Lowest Cost of Ownership.

The flexibility and high capacity are supported by several additional standard features securing a guaranteed overall efficiency of 99+% with one supervisor only concluding in the Lowest Cost of Ownership.

The COOKIEBOT XP is a fully Houdijk designed and build system, meeting all important and suitable criteria for the typical bakery conditions, whereby ease of operation, change-over, cleanability, maintainability, overall efficiency, 24/7 robustness can be recognized.

Next to the COOKIEBOT XP, Houdijk will exhibit the HOUDIJK CAPPER which – in its third design release – has proven in worldwide successful materialized projects over the last decades to be the benchmark in depositing and capping technology. The HOUDIJK CAPPER offers – with toolless exchangeable size parts designed according to POKA YOKE philosophy – ultimate flexibility between different product sizes and shapes.

The HOUDIJK CAPPER offers – with toolless exchangeable size parts designed according to POKA YOKE philosophy – ultimate flexibility between different product sizes and shapes. Various materials such as aerated fat creams, jams, marshmallow or chocolate can be deposited whereby the “No product / No deposit” functionality prevents wasting expensive deposit material and pollution of the solution.

Various materials such as aerated fat creams, jams, marshmallow or chocolate can be deposited whereby the “No product / No deposit” functionality prevents wasting expensive deposit material and pollution of the solution.

The HOUDIJK CAPPER offers the highest possible output with capacities of up to 6.500 sandwiches/minute equal to the capacity of two 4-lane stencil creamers.

The flexibility and high capacity are supported by several additional standard features securing a guaranteed overall efficiency of 99+% with one supervisor only in combination with a digital start up after product change over.

In its third design release in combination with the worldwide successful materialized projects, the HOUDIJK CAPPER has proven to be the benchmark in depositing and capping technology.

The Houdijk team is looking forward to welcome you at our booth in hall 3 / stand A19 to discuss your projects and present to you our solutions with guaranteed success.