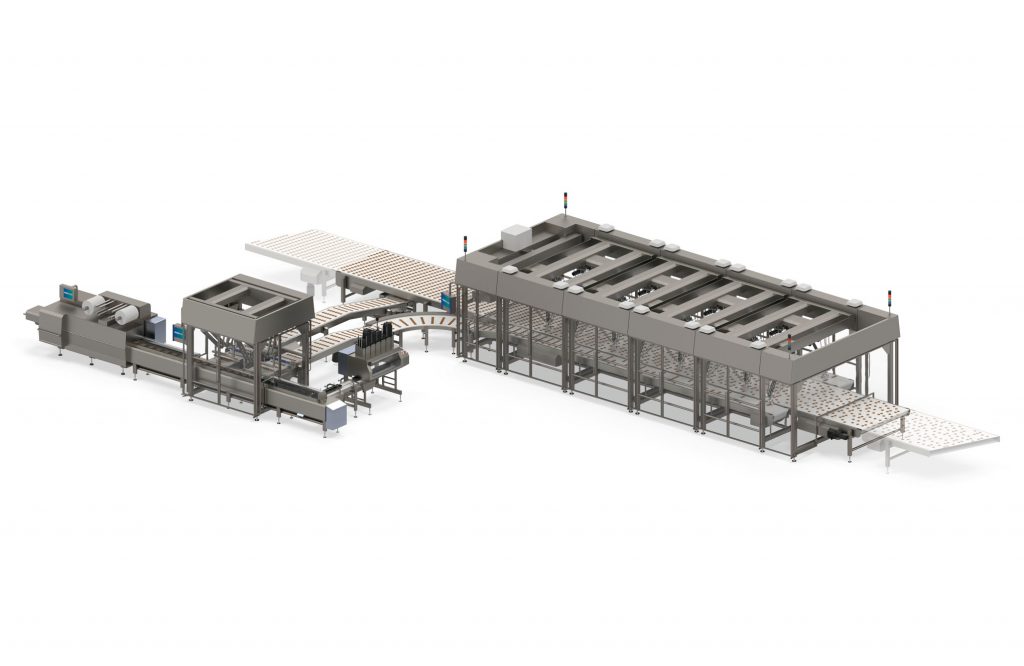

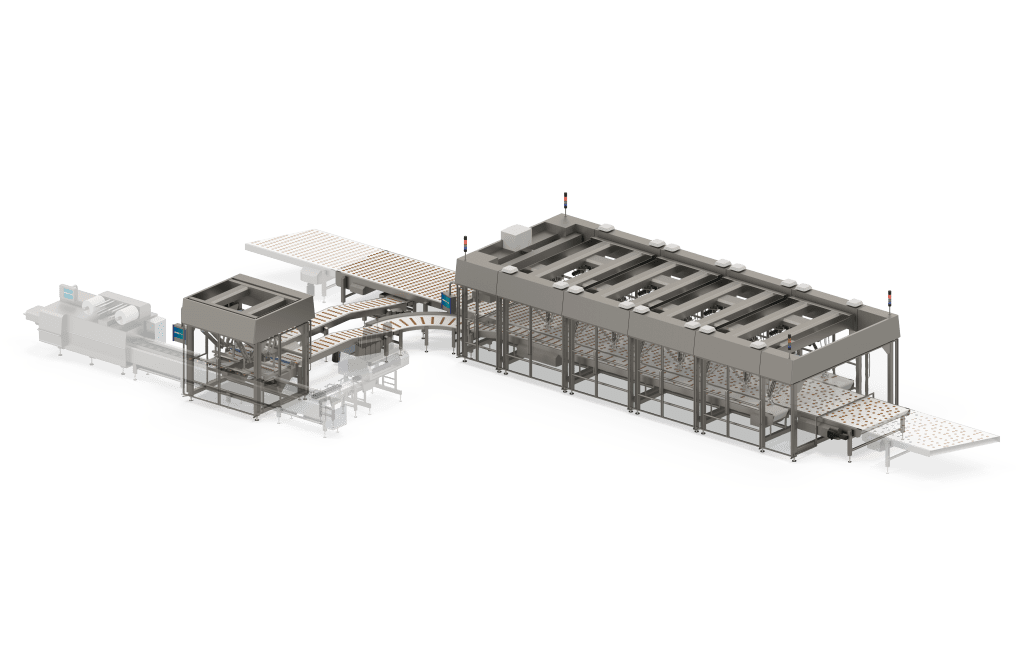

First the COOKIEBOT system is used for forming organised product patterns (rows and lanes). These rows and lanes are then fed to the COOKIEDOZER consisting of a horizontal forming plate and a pusher.

By pushing a row of products over and through the forming plate, a slug or a pile can be created and is directly fed into the FLEX WRAP.

From these two conveyors the pattern of products is fed to the COOKIEDOZER module. The COOKIEDOZER functionality is patented and designed to handle a wide array of different product types, sizes, shapes and package configurations which are:

- Product on edge in slug

- Product on edge in slug in tray

- Product in pile

- Product in pile in tray

- Product on edge in cavity tray

All configurations are then directly loaded into the FLEX WRAP flowrapper.