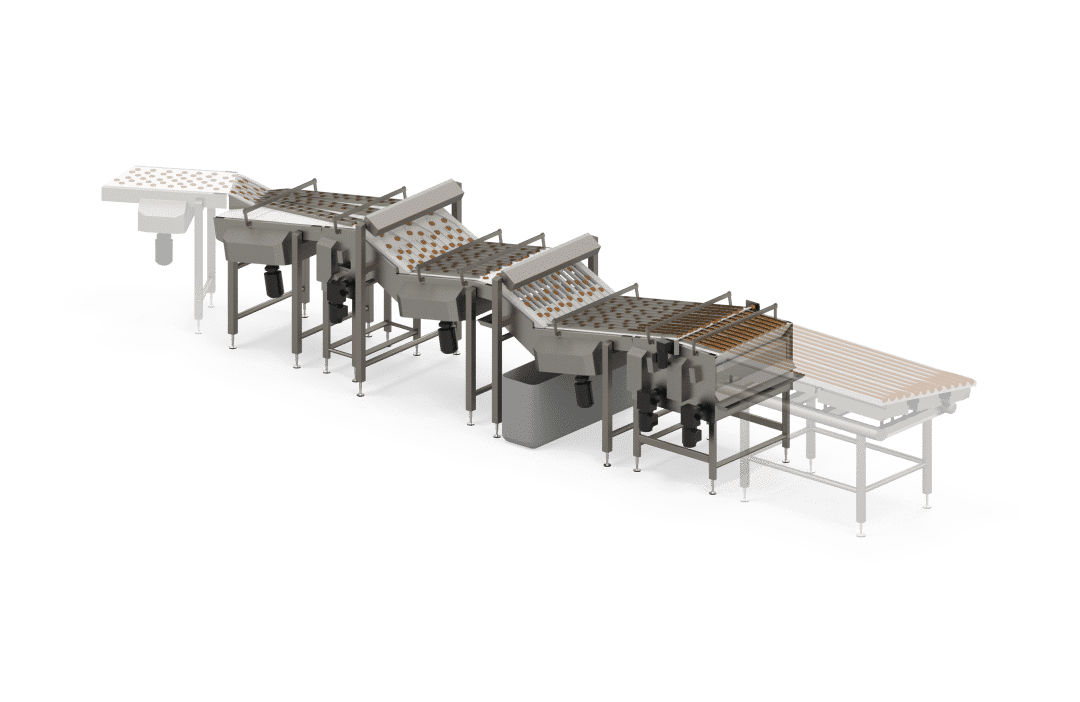

Houdijk has various systems to handle capacities of up to and above a 1.000 products per minute per lane.

A typical execution of such a line offers multiple and consecutive functional steps to enhance overall efficiency and minimize waste.

The incoming products are received and guided via a dribble board onto a conveyor featuring side guides.

The product lane pitch is expanded before the dribble board and not on the dribble board, thereby avoiding:

- Different travel speeds over the width of the ‘expanding’ dribble board, often causing downstream issues due to different spacing in the lanes and/or even shingling.

- Product migration between lanes resulting in an imbalance on the Vibratory System.

Product speed and spacing between the products are kept as low and constant as possible by using (intermediate) metering conveyor(s). The lowest possible speed will ensure a higher efficiency.

To properly match the row rate of the oven with the row rate of a loader, lane expansion is often required. Especially with the market trend to smaller packages this mismatch can cause ‘overcharging’ of the loader. Lane expansion is then the preferred solution, to keep the loaders at a ‘normal’ and more efficient speed rate.

To protect downstream processes a VISION SELECTOR can be added, prior to actual product handling.