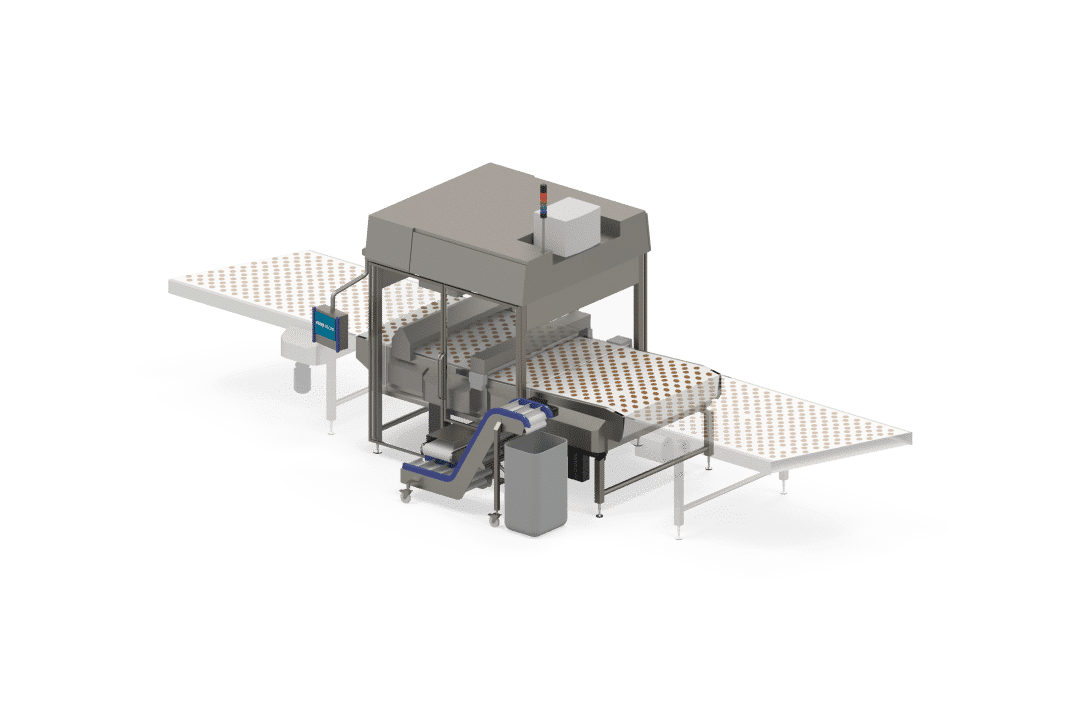

To improve the total line efficiency, all products are inspected by the VISION SELECTOR.

The location of the VISION SELECTOR is always chosen before the product flow is captured between guides.

The objective of this system is to ‘protect’ the downstream equipment by rejecting products that may cause stoppages (and possibly waste) or require manual interference by the supervisor.

The standardized VISION SELECTOR comprises an array of camera’s to inspect the products regarding circumference, height, shape and position, to qualify or disqualify products. Furthermore the VISION SELECTOR features an individual product reject unit for any disqualified products.

The VISION SELECTOR system collects data on product quality (defects, over time and over the belt width) which can be shared with your MES system.

Additional quality control (e. g. color, surface) can be integrated based on customer specifications.