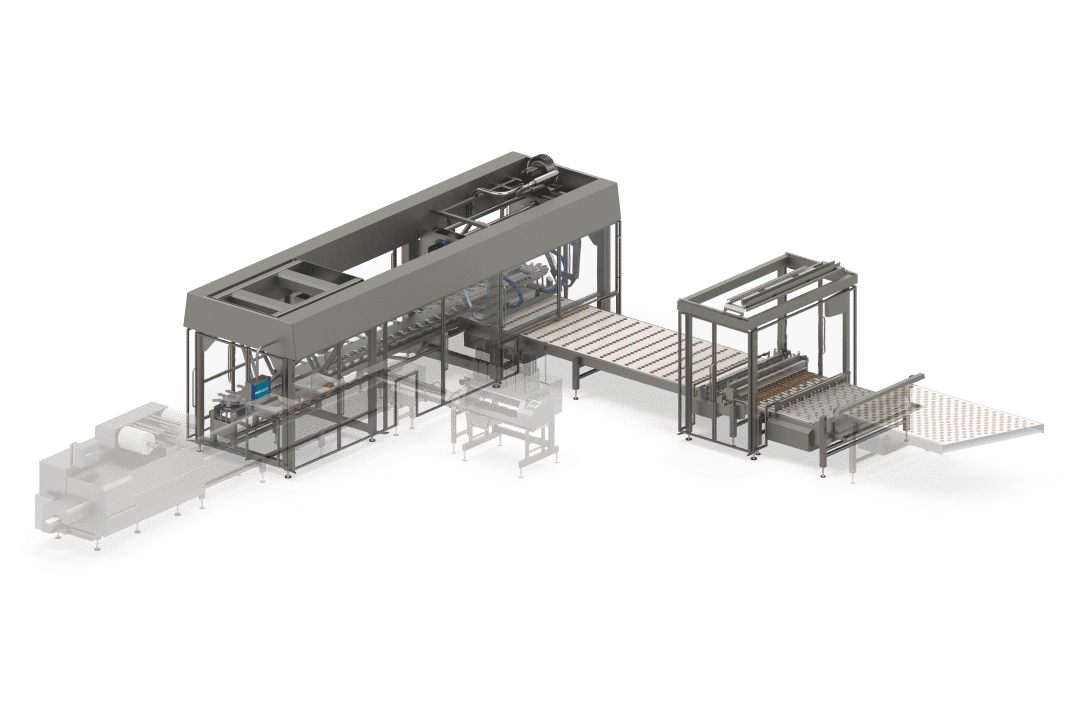

The product flow is fed to the FLEX CROSS LOADERS in rows and lanes, coming from the HOUDIJK CAPPER.

To ensure proper lanes and rows a re-alignment system can be provided just prior to the loaders.

Each loader picks up its designated rows and forms these – through a COOKIEDOZER – into slugs or piles, alternatively directly into trays. The slugs, piles or trays are then wrapped via a FLEX WRAP.