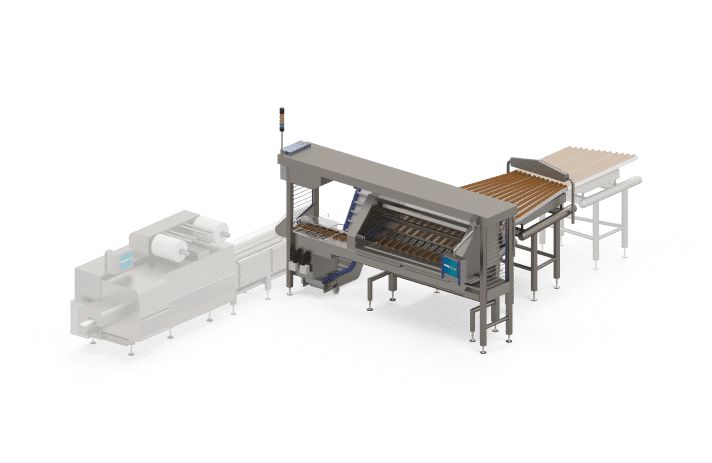

The CLIPPER is suitable for handling various shapes of biscuits or crackers. The CLIPPER in combination with the Houdijk product handling system offers the most gentle and highest efficient volumetric loader in the market.

A VIBRATORY BUFFER feeding the CLIPPER will ensure a continuous product supply with well controlled back pressure.

Two basic executions are available:

CLIPPER –Biscuit On Edge slug loading, into flowpack. The desired slug count is first gradually build up in the SLUGMASTER, the product overhead flightbar conveyor. Once the slug count is completed the slugs are fed into the cross positioned FLEX WRAP. Capacities of 300+ packs/minute per CLIPPER can be achieved.

CLIPPER – Biscuit On Edge slug loading, in trays. The desired slug count is first gradually build up in the SLUGMASTER. In addition the SLUGMASTER features a TRAYMASTER, consisting of:

– an automatic tray denester

– a tray infeed conveyor

– a tray synchronization unit

– a tray outfeed conveyor

The TRAYMASTER ensures synchronisation of the empty trays with created slugs in the SLUGMASTER whereby completed slugs are dosed gently into the tray cell. This solution offers a quick change-over between trays featuring 1, 2, 3 or 4 cells per tray.