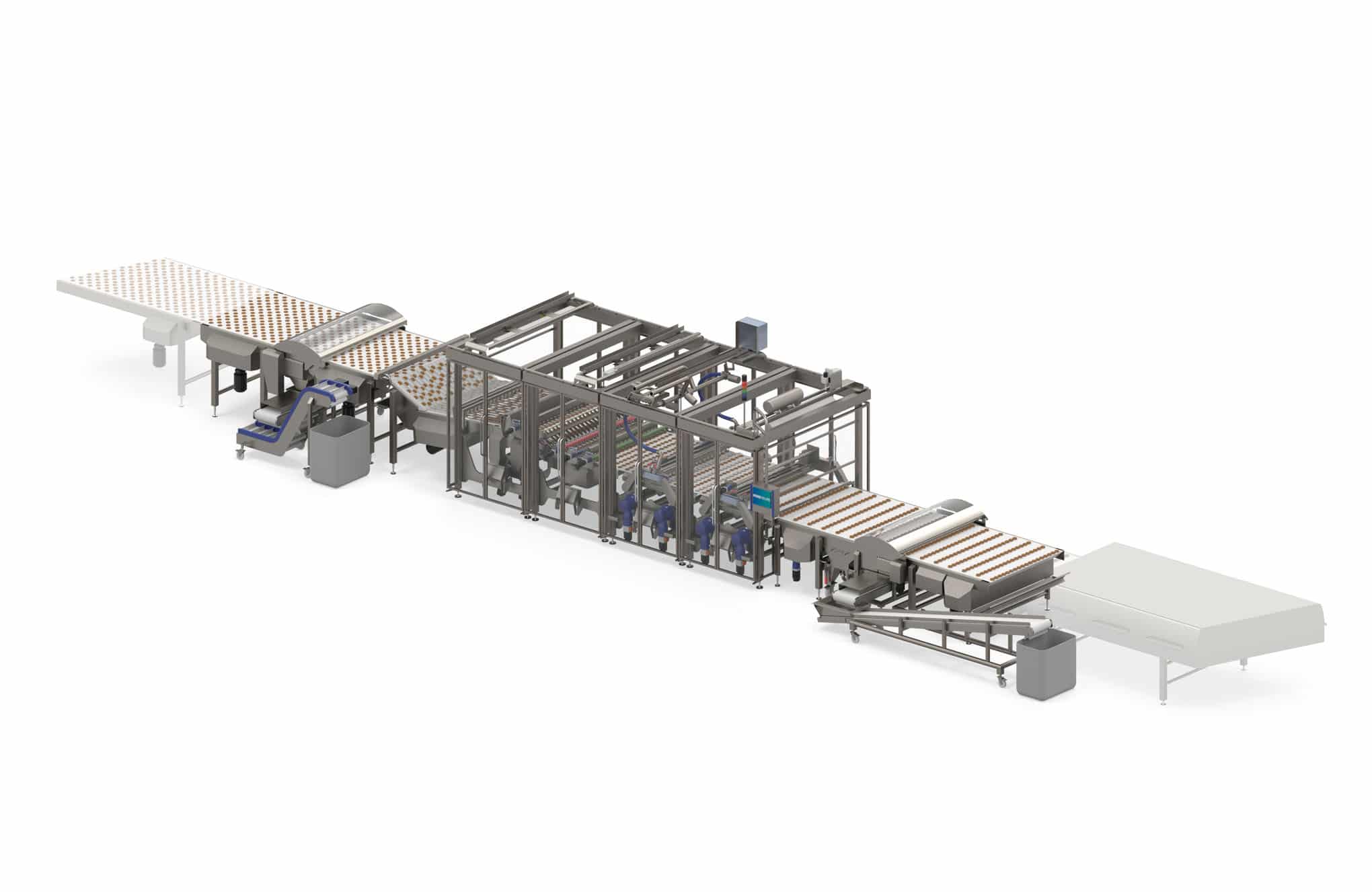

The HOUDIJK CAPPER is a flexible system, designed to allow the production of a variety of different sandwich products.

The dedicated base cake size parts – poka yoke designed – are easy and toolless exchangeable to assure repeatability of settings and an instant start-up after a change-over.

Size parts are ergonomically designed for easy exchange by operators. For heavier parts – like e.g. the HOUDIJK MANIFOLD – a lifting tool is provided.

Size parts, which are not in use can be properly stored in special designed trolleys. This assures long lasting protection of these parts.

In case a deposit material change requires supply pipe cleaning, the HOUDIJK CAPPER can be connected to the CIP cleaning system of the cream kitchen.

The HOUDIJK MANIFOLD can be cleaned off line (COP), facilitated by a cleaning trolley and controls, enabling nozzle cleaning in groups to create a higher water flow.